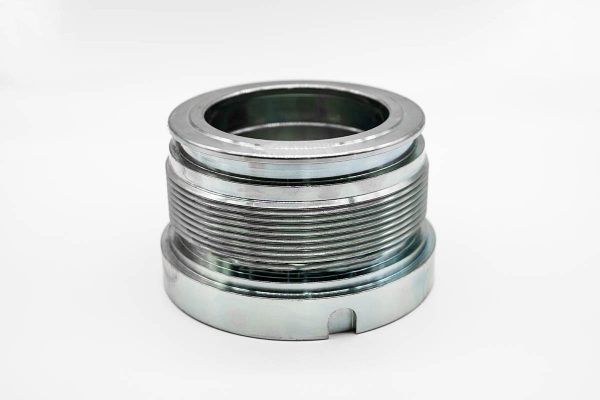

The wide and well-assorted range of machines allows the most complex machining of parts according to the customer’s design, starting from steel mouldings, cast iron castings or rolled bar.

The turning department can count on both vertical and horizontal lathes, motorised and in some cases served by anthropomorphic arms that allow a wide range of sizes.